Finally there is an introduction to the standard that governs GD&T in the US, together with a mention of the symbols, rules and vocabulary. Other areas covered include the importance of selecting appropriate GD&T early in the design cycle, together with the range of advantages this provides. These defects reduce competiveness and ultimately cost money, as parts are produced which are not fit for purpose. Poor understanding of GD&T is often one of the causes of engineering change orders and the subsequent drawing modifications all too common in many SMEs. Examples are given for the design, production and quality functions, demonstrating how it specifically benefits each team. This includes how it impacts different teams throughout the organisation. Solid explanation of why GDT knowledge and training is important for your SME manufacturing or engineering business. Why GD&T - Geometric Dimensioning & Tolerancing (Courtesy of Tec-Ease). The short video steadily describes the key ideas and the impact on allowances and tolerancing, together with what it means for the design engineer and the machinist reading the engineering drawing. Crystal clear explanation of what this means for a machined component. Register for PC-DMIS GD&T Classes at: Īllowances MMC and LMC (Courtesy of the AutoCAD Channel): Maximum material condition and least material condition, core elements of geometric tolerancing. Beyond a mere theory course, this class focuses on practical take-home skills that the student can apply right away in a production manufacturing environment. GD&T Class for Production Engineering Application (Courtesy of Hexagon Metrology)Ī new GD&T class focusing on ASME Y14.5: 19 standards, with emphasis on the practical application of these standards to real-world production measuring practices with PC-DMIS software.

The video rounds off with examples you can try to test your knowledge. Also how the standard can help you with examples of typical fits you may wish to select depending on the function you require.

#Iso fits and tolerances chart pdf how to#

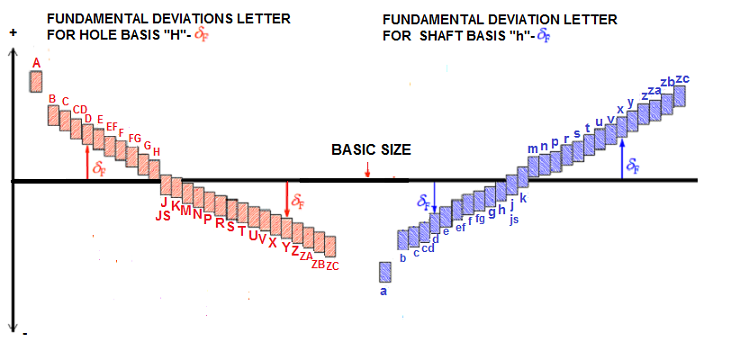

Worked examples demonstrate how to use the chart to select an appropriate fit. The short video features an explanation of hole and shaft charts and how to use them, including permissible clearances potentially for lubricants. Limits and Fits, Selecting Size Tolerances (Courtesy of Geotol Pro): A good introduction into the topic. The main types of fit are covered including running & sliding fits, locational fits and force fits. Ideal for training and refreshing knowledge.

Exercises and quizzes test your understanding throughout, enabling the subject matter to be fully understood. Other areas comprehensively covered include material conditions and fixed and floating fasteners, again with worked examples. Geometric and coordinate tolerancing methods are compared with plenty of illustrations and examples of typical component features. Finally tolerances of location illustrate true position, concentricity and symmetry. Tolerance of profile feature profile of a line and profile of a surface. Tolerances of runout reveal circular runout and total runout.

Tolerances of angularity covered include angularity, perpendicularity and parallelism. Tolerances of form shown include straightness, flatness, circularity and cylindricity.

Geometric characteristic symbols that apply to manufactured Geometric Tolerancing & Coordinate Tolerancing):Ī comprehensice, yet clear explanation with worked examples of all key features. Extreme variations, sizes, form and tolerances are illustrated. Use the Limits, Fits and Tolerances info below either personally or with colleagues to learn, retrain, demonstrate and above all get on.ĭimensional Tolerancing (inc. We also cover Geometric Dimensioning and Tolerances (GD&T) fundamentals for your convenience. It is the difference between the maximum and the minimum limits for the dimension. Tolerance on the other hand is the total amount that a specific dimension is permitted to vary. Thus, the fit between members that move or rotate relative to each other, such as a shaft rotating in a bearing, is considerably different from the fit that is designed to prevent any relative motion between two parts, such as a wheel attached to an axle'. The character of the fit depends upon the use of the parts. The degree of tightness or looseness between two mating parts that are intended to act together is known as the fit of the parts. 'The extreme permissible values of a dimension are known as limits. In order to understand the terms, a useful succinct definition is provided by McGraw Hill:

0 kommentar(er)

0 kommentar(er)